Moisture Control Layers: The Key to Longevity in Masonry and EIFS Systems

Introduction

In the realm of building envelope design, moisture control is paramount. The integrity and longevity of structures, particularly those utilizing masonry and Exterior Insulation and Finish Systems (EIFS), hinge on effective moisture management. These systems, while popular for their aesthetic appeal and energy efficiency, are susceptible to moisture-related issues that can compromise performance and durability. Understanding the role of moisture control layers is essential for architects, facade engineers, building envelope consultants, and commercial contractors aiming to ensure the longevity and functionality of these systems.

Understanding Moisture Control Layers

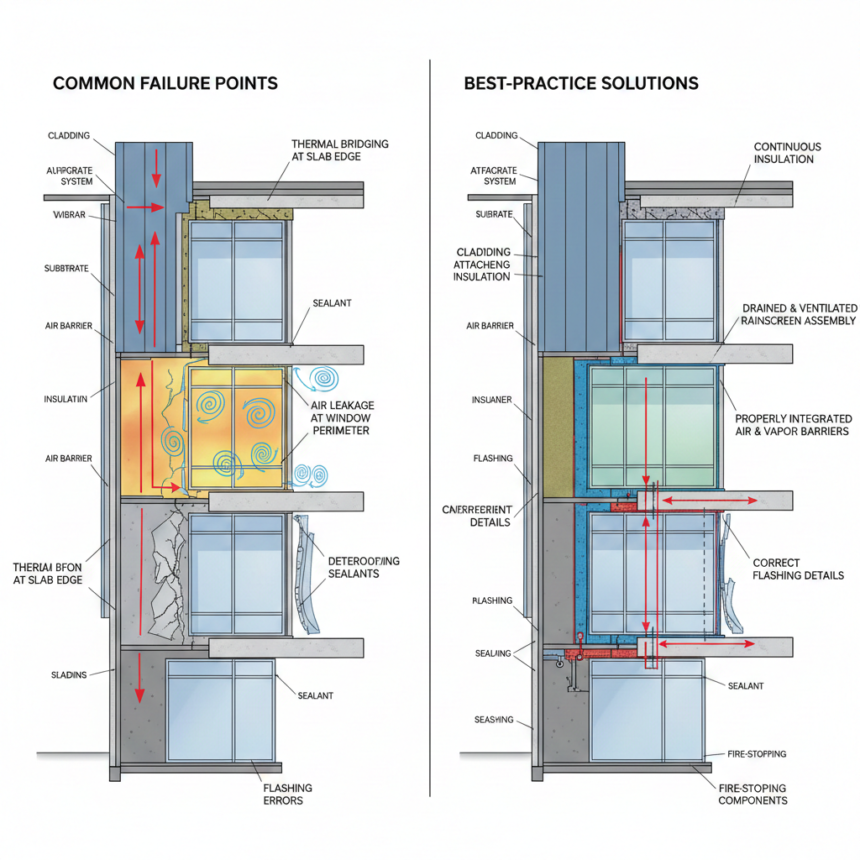

Moisture control layers are critical components of building envelopes, designed to manage water ingress and egress. They include water-resistive barriers (WRBs), vapor retarders, and drainage planes, each serving distinct functions to protect the building from moisture damage.

Water-Resistive Barriers (WRBs)

WRBs are essential in preventing water penetration into the building envelope. In masonry and EIFS systems, WRBs act as a shield against rainwater and other forms of moisture. They are typically installed behind cladding materials, providing a secondary line of defense.

Vapor Retarders

Vapor retarders control the movement of water vapor through the building envelope. Their placement and type depend on climate conditions and the specific requirements of the building. Inappropriate use or placement can lead to condensation issues, which can be detrimental to both masonry and EIFS systems.

Drainage Planes

Drainage planes facilitate the movement of water away from the building envelope. In EIFS systems, for example, a drainage plane can prevent water from becoming trapped behind the finish, which could otherwise lead to deterioration of the insulation and structural components.

Practical Considerations in Design and Installation

Climate Considerations

The choice and placement of moisture control layers must be informed by the local climate. In humid environments, vapor retarders should be carefully selected to prevent condensation within the wall assembly. Conversely, in colder climates, the focus should be on preventing moisture from entering and freezing within the system.

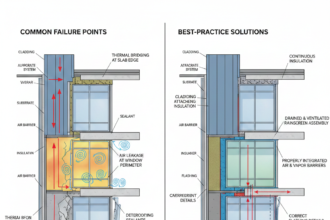

Compatibility and Integration

Ensuring compatibility between different moisture control layers and other building components is crucial. In masonry systems, for instance, the integration of WRBs with flashing and weep holes must be meticulously planned to ensure effective drainage and moisture management.

Installation Best Practices

Proper installation is vital to the performance of moisture control layers. Misalignments, punctures, or improper sealing can compromise the entire system. Regular training and adherence to manufacturer guidelines are essential to avoid these pitfalls.

Common Pitfalls and How to Avoid Them

Inadequate Detailing

One of the most common pitfalls in moisture control is inadequate detailing at junctions, penetrations, and terminations. These areas are prone to leaks and require careful attention during design and installation.

Overlooking Maintenance

Even the best-designed moisture control systems require regular maintenance. Inspections should be conducted to identify and rectify any damage or wear, ensuring the system continues to perform effectively over time.

Misunderstanding Material Properties

A lack of understanding of the properties of moisture control materials can lead to inappropriate selections. For example, using a vapor barrier in a location where a vapor retarder is needed can lead to moisture accumulation and damage.

Code Implications

Building codes play a significant role in the design and implementation of moisture control systems. Compliance with local codes ensures that the building envelope meets minimum performance standards, but exceeding these standards can provide additional assurance of longevity and durability.

Code Compliance

Architects and engineers must stay informed about the latest code requirements related to moisture control. This includes understanding the specific requirements for WRBs, vapor retarders, and drainage systems in their jurisdiction.

Performance Testing

Performance testing of moisture control systems is often required to demonstrate compliance with building codes. This testing can include water penetration tests, air barrier tests, and thermal performance evaluations.

Conclusion

Moisture control layers are indispensable to the longevity and performance of masonry and EIFS systems. By understanding the roles of WRBs, vapor retarders, and drainage planes, and by considering climate, compatibility, and installation practices, professionals can design and construct building envelopes that withstand the test of time. Avoiding common pitfalls and adhering to code requirements further ensures that these systems perform as intended, safeguarding the building’s structural integrity and aesthetic appeal. As the industry continues to evolve, staying informed and proactive in moisture management will remain a cornerstone of successful building envelope design.

ng, execution, and adaptability to ensure the longevity and performance of our built environment.