The construction industry is experiencing a major transformation driven by automation. From robotics and prefabrication to 3D printing and AI-powered monitoring, automated systems are reshaping how materials are produced, assembled, and delivered.

What was once a slow, labor-intensive process is now becoming faster, safer, and more precise helping companies reduce waste, improve quality, and meet the growing demand for sustainable buildings.

The Shift Toward Automated Construction

Automation bridges the gap between manufacturing and construction. It introduces efficiency through robotics, machine learning, and digital control systems, reducing dependence on manual labor while increasing consistency and accuracy.

As global projects grow in scale and complexity, automation allows teams to meet deadlines and maintain quality standards even under challenging conditions.

Key Automated Processes Transforming the Industry

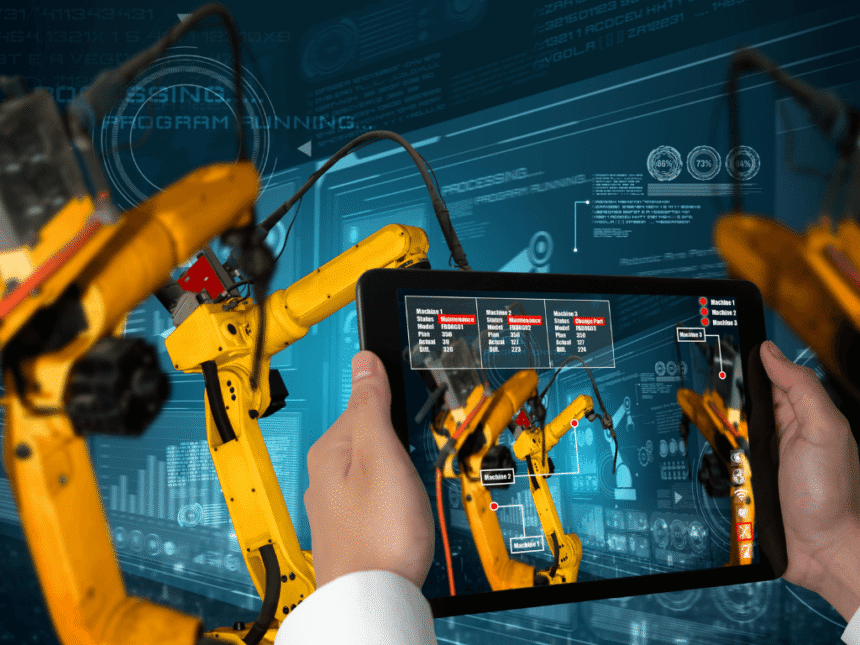

1. Robotics in Manufacturing and Assembly

Robotic arms and automated fabrication machines are now used for welding, cutting, and assembling building components with unmatched precision.

In prefabrication facilities, robots produce façade panels, beams, and modular components faster than traditional crews while maintaining consistent quality.

2. 3D Printing in Construction

3D printing, or additive manufacturing, enables the creation of complex structures layer by layer using concrete, polymers, or composites.

This method minimizes material waste and shortens construction timelines while allowing designers to experiment with organic and customized forms.

3. Automated Material Handling and Logistics

Automated cranes, drones, and conveyor systems streamline the movement of materials from factory to site. These technologies reduce handling time, minimize on-site congestion, and enhance worker safety.

4. AI-Driven Quality Control

Artificial intelligence plays a key role in quality assurance. Cameras and sensors detect defects or inconsistencies during production, allowing real-time adjustments. This automation ensures every product meets design and safety standards before installation.

5. Prefabrication and Modular Construction

Automation has made prefabrication more advanced and accessible. Factories equipped with CNC machines, robotic assembly lines, and automated inspection systems deliver ready-to-install components that reduce construction time and waste.

Advantages of Automation in Construction Manufacturing

Automation enhances nearly every aspect of building production:

Speed and Efficiency: Projects can be completed faster with reduced downtime.

Consistency and Precision: Automated machines maintain accuracy at every stage.

Cost Reduction: Lower labor requirements and less waste translate into significant savings.

Safety: Reducing manual intervention minimizes on-site accidents and exposure to hazardous conditions.

Sustainability: Controlled production environments generate less waste and improve material efficiency.

How Automation Supports Sustainable Building Goals

Automated processes contribute directly to sustainability by optimizing material use, lowering emissions, and improving energy performance during manufacturing.

For example, precision cutting and digital fabrication reduce waste by up to 40 percent, while efficient logistics minimize transportation emissions.

Combined with renewable energy sources and smart manufacturing, automation is helping the industry transition toward a more circular, low-carbon economy.

The Future of Automated Construction

The next phase of automation will focus on full integration between design, production, and installation.

Digital twins, AI modeling, and cloud-based monitoring will allow every part of the construction process to be simulated, tracked, and optimized in real time.

As technology evolves, automation will no longer be an advantage—it will be a necessity for firms seeking efficiency, safety, and sustainability in the modern construction era.

Image Credits: Freepik