Behind every energy-efficient and durable building lies a hidden hero: the air barrier. Often overlooked, air barriers are critical components that control airflow through a building’s envelope, protecting its structure, improving performance, and maintaining indoor comfort.

For architects, understanding the science behind air barriers is essential to designing buildings that meet modern energy standards and sustainability goals.

What Is an Air Barrier and Why It Matters

An air barrier is a system of materials designed to control the movement of air into and out of a building.

Uncontrolled air leakage increases energy costs, causes condensation, and can lead to mold growth or structural deterioration.

A properly designed air barrier reduces these risks by ensuring that conditioned air stays inside while outdoor air and moisture remain out. The result is improved thermal efficiency, better indoor air quality, and greater occupant comfort.

The Science Behind Air Movement

Air moves through the building envelope due to three main forces: pressure differences, wind, and temperature variations. These forces push and pull air through cracks, gaps, and joints if the barrier system is not continuous.

Air leakage contributes significantly to heating and cooling losses. Even small openings can cause major inefficiencies making proper air barrier design a key factor in achieving energy savings and code compliance.

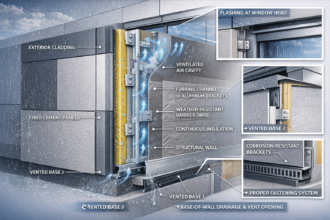

Key Components of an Effective Air Barrier System

1. Continuity

An air barrier must be continuous across all parts of the building envelope walls, roofs, windows, and foundations. Every joint, seam, and transition point needs careful detailing to prevent leaks.

2. Durability

Materials used in air barriers must withstand temperature shifts, UV exposure, and mechanical stress. Modern systems include durable membranes, sealants, and coatings that maintain integrity for decades.

3. Compatibility

Different materials must bond and perform together without compromising the barrier’s continuity. Architects should ensure compatibility between membranes, adhesives, and substrates to prevent system failure.

4. Airtightness Verification

Testing the completed system is essential. Blower door and smoke tests confirm that the design achieves the required airtightness level before occupancy, avoiding future performance issues.

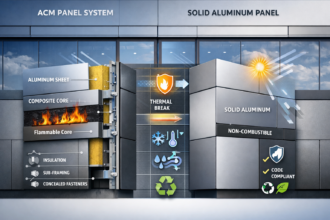

Types of Air Barrier Materials

1. Sheet Membranes

These are pre-manufactured rolls applied to the building’s surface. They provide strong and consistent coverage and are ideal for large wall or roof areas.

2. Fluid-Applied Membranes

Sprayed or rolled onto the substrate, these create seamless protection around complex details and penetrations reducing the potential for leaks.

3. Self-Adhered and Mechanically Fastened Systems

Self-adhered barriers simplify installation and reduce errors, while mechanically fastened options are suitable for projects requiring high vapor permeability.

Testing and Quality Control

Verification testing is critical to ensure the barrier performs as designed.

ASTM E779 and ASTM E2357 are common test standards for measuring air leakage in whole buildings and wall assemblies.

Regular inspection and testing during construction help detect defects early, ensuring long-term reliability and compliance with ASHRAE 90.1 and other performance codes.

Air Barriers and Sustainable Design

Air barriers contribute directly to energy efficiency and carbon reduction goals. By minimizing air leakage, they reduce HVAC loads and support net-zero design strategies.

They also enhance indoor environmental quality by preventing pollutants and allergens from entering the building making them an essential element of both comfort and sustainability.

The Future of Air Barrier Technology

The next generation of air barriers will incorporate smart materials that respond to humidity and temperature changes.

With improved vapor control, enhanced durability, and integration into digital design workflows, these systems will continue to evolve as architects push toward higher performance standards.